Invariants Mesa Auxiliar Oro

4545 EUR

Envío en 11-12 semanas

Descubra las modernas piezas de fibra de carbono de Frisoli: inspirados por las fascinantes siluetas de los aviones fabricados en la empresa familiar, Romina y Michele empezaron a diseñar y producir muebles modernos y piezas decorativas con un estilo único, utilizando materias primas innovadoras.

El contenido de esta página ha sido traducido automáticamente. Visitar el sitio en ingles

¿Cuál es la filosofía de la marca Frisoli?

Nos inspiramos en las fascinantes siluetas de los aviones que vemos a diario en nuestra empresa de fabricación y en su capacidad para despertar nuestras emociones más íntimas. Nuestra idea es recrear la emoción de volar inherente a los objetos diseñados y creados para este fin específico. Colecciones como "NOT FOR FLY" están pensadas para integrarse en nuestra vida cotidiana, el nombre deriva de una especificación técnica que se encuentra en todos los componentes de los aviones que no pueden utilizarse por razones de defecto. Así pues, Frisoli nació del deseo de dar nueva vida a los objetos que nos rodean en nuestra empresa familiar, para que puedan, a su vez, inspirar la vida cotidiana. El diseño es la herramienta que nos permite añadir un toque artístico y fascinante a esos objetos, permitiéndonos disfrutar plenamente de ellos cada día.

La principal característica de su marca es el uso de fibra de carbono, un material utilizado en el sector aeronáutico. ¿En qué se inspira esta elección y cuáles son las ventajas de utilizar materiales tan particulares?

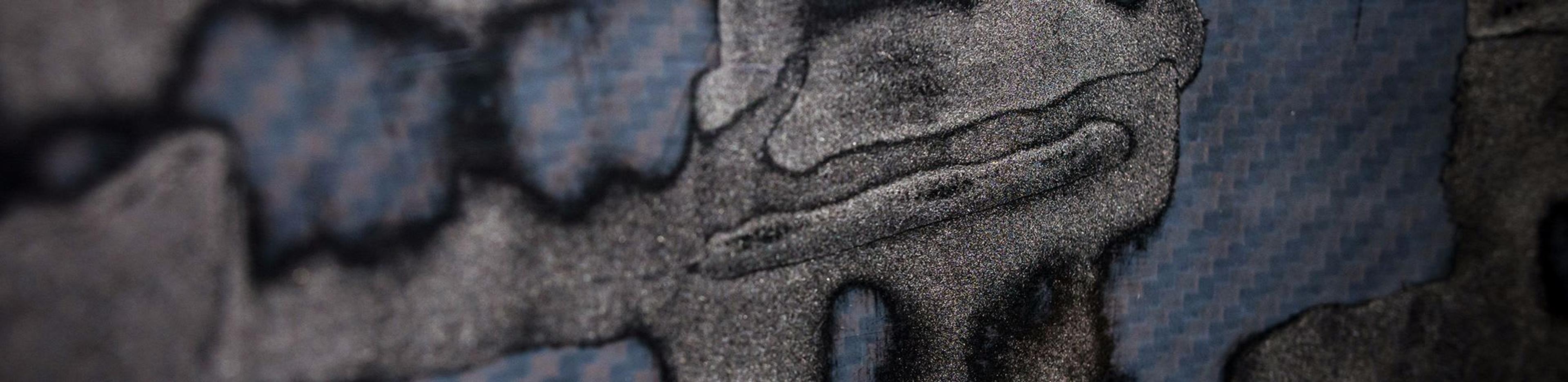

Los materiales que empleamos son los utilizados por la industria aeronáutica, e incluyen, entre otros: fibras compuestas, como fibra de carbono, fibra de vidrio, kevlar y otros materiales derivados del fenol. Los armazones de los aviones también se fabrican con metales como el aluminio y el acero. La elección de los materiales se deriva principalmente de nuestras capacidades tecnológicas y de fabricación. Nuestra experiencia en el trabajo con materiales compuestos se basa en el hecho de que la fibra de carbono es el principal material utilizado para los componentes de aviones y helicópteros que fabrica nuestra empresa. Los materiales compuestos fascinan sobre todo por su aspecto y textura similares a los tejidos, y pueden cortarse a medida para adaptarse a cualquier dimensión, del mismo modo que un sastre corta la tela para sus modelos. Este "tejido" puede modelarse y tratarse con resina para que sea más resistente que el metal.

La segunda característica fascinante de estos materiales compuestos es su mínimo grosor, que contribuye a su ligereza natural. De las fibras compuestas pueden derivarse formas intrigantes y atrevidas, cuyo grosor oscila entre 2 y 5 milímetros, lo que confiere a los objetos resultantes un carácter dinámico y esbelto a la creación.

La última característica que distingue a los materiales de Frisoli es la experimentación visual y de diseño que hemos llevado a cabo durante casi dos años y que seguiremos cultivando. Las fibras compuestas no se dejan en su color original, sino que se presentan en tonos vivos, moteadas y con acentos decorativos.

¿Cómo describiría la estética de sus productos? ¿Qué los hace únicos?

Todas nuestras creaciones se someten al mismo flujo de producción que los aviones, vertiendo la emoción del propio proceso en cada pieza. No obstante, la inspiración para nuestros diseños y estética no proviene de las formas de los aviones en sí, sino que se inspira en el mundo artístico. Nos inspiramos en artistas y movimientos artísticos, y el material compuesto se utiliza de forma similar al lienzo de un pintor.

Una de las características que hacen únicas nuestras creaciones es sin duda el medio. Tanto los materiales compuestos como los metales se tratan para transformar sus cualidades estéticas. Cada pieza se compone de una mezcla única de fibras, patrones, colores y luminosidades.

Nuestras creaciones son únicas porque se ensamblan y acaban exclusivamente a mano, y la singularidad de su proceso de fabricación y los patrones de su superficie es lo que hace que las creaciones de Frisoli sean fácilmente reconocibles. Nuestra experiencia en el trabajo de estos materiales va siempre de la mano de una gran atención a las cualidades estéticas de nuestros productos.

¿Cuál es la etapa más fascinante en la creación de un producto Frisoli?

Todas las fases de fabricación tienen un atractivo distinto, pero si tuviéramos que elegir una, elegiríamos la polimerización, que es el proceso durante el cual la pieza se "cuece" en un autoclave, donde se endurece dentro de su molde. La fascinación reside en ver cómo el material, parecido a un tejido, cobra vida como objeto sólido.

¿Cuáles son sus proyectos futuros? ¿Puede contarnos más?

A partir del año que viene, lanzaremos una nueva colección nacida de la colaboración con Domenico De Palo, un diseñador muy conocido por sus anteriores colaboraciones con marcas como Antonio Lupi, Visionnaire y Rugiano. Al mismo tiempo, lanzaremos nuestra nueva colección de vajillas, en la que experimentaremos nuevas formas de trabajar la fibra de vidrio. Les mantendremos informados.

4545 EUR

Envío en 11-12 semanas

3635 EUR

Envío en 11-12 semanas

1990 EUR

Envío en 11-12 semanas

6500 EUR

Envío en 9-10 semanas

4670 EUR

Envío en 13-14 semanas

2015 EUR

Envío en 9-10 semanas

BottegaNera transforma los muebles en obras de arte expresivas, fusionando la precisión de la arte…

Arraigado en una antigua tradición familiar toscana, Borzalino aborda el futuro de la artesanía a …